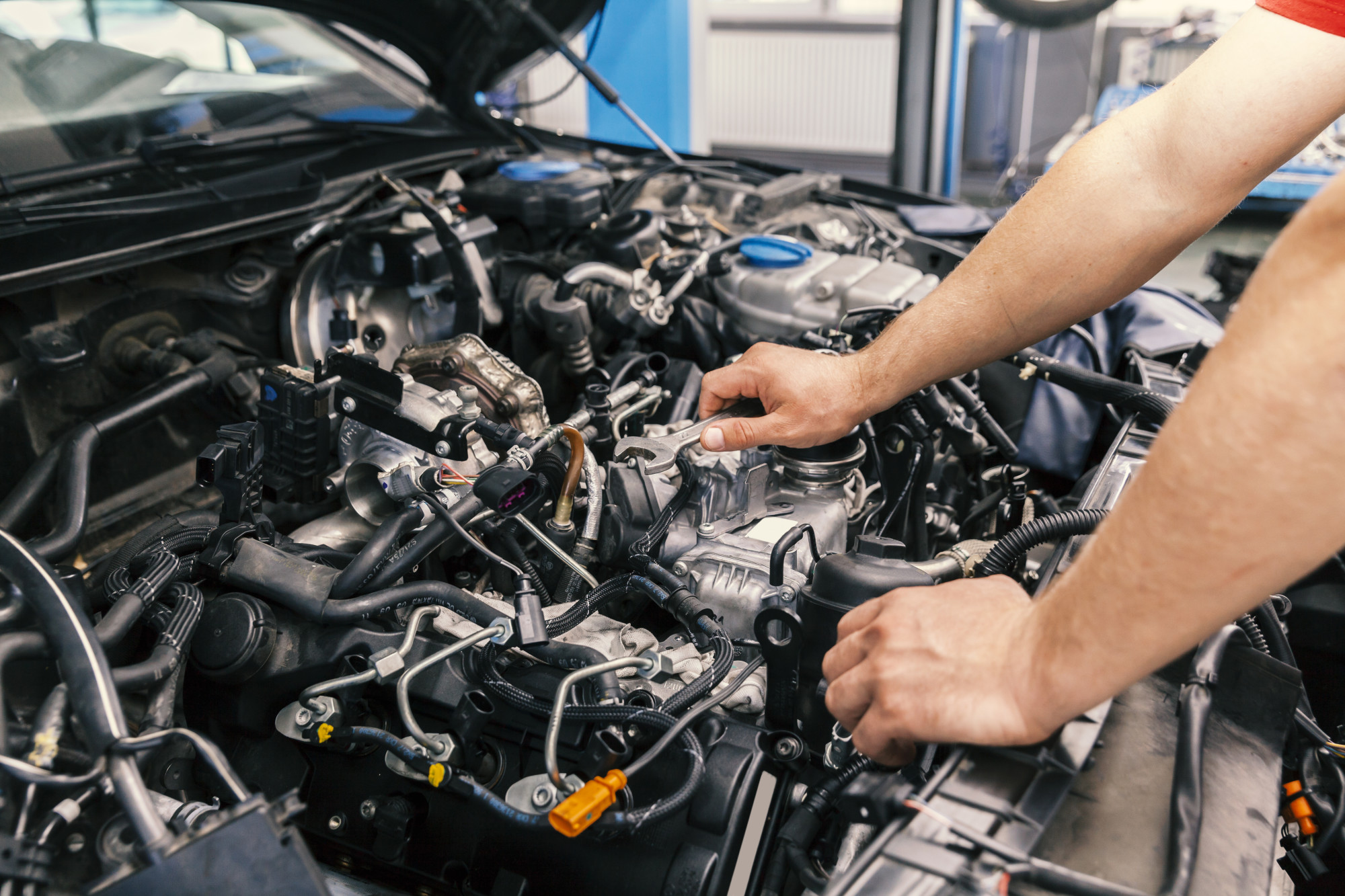

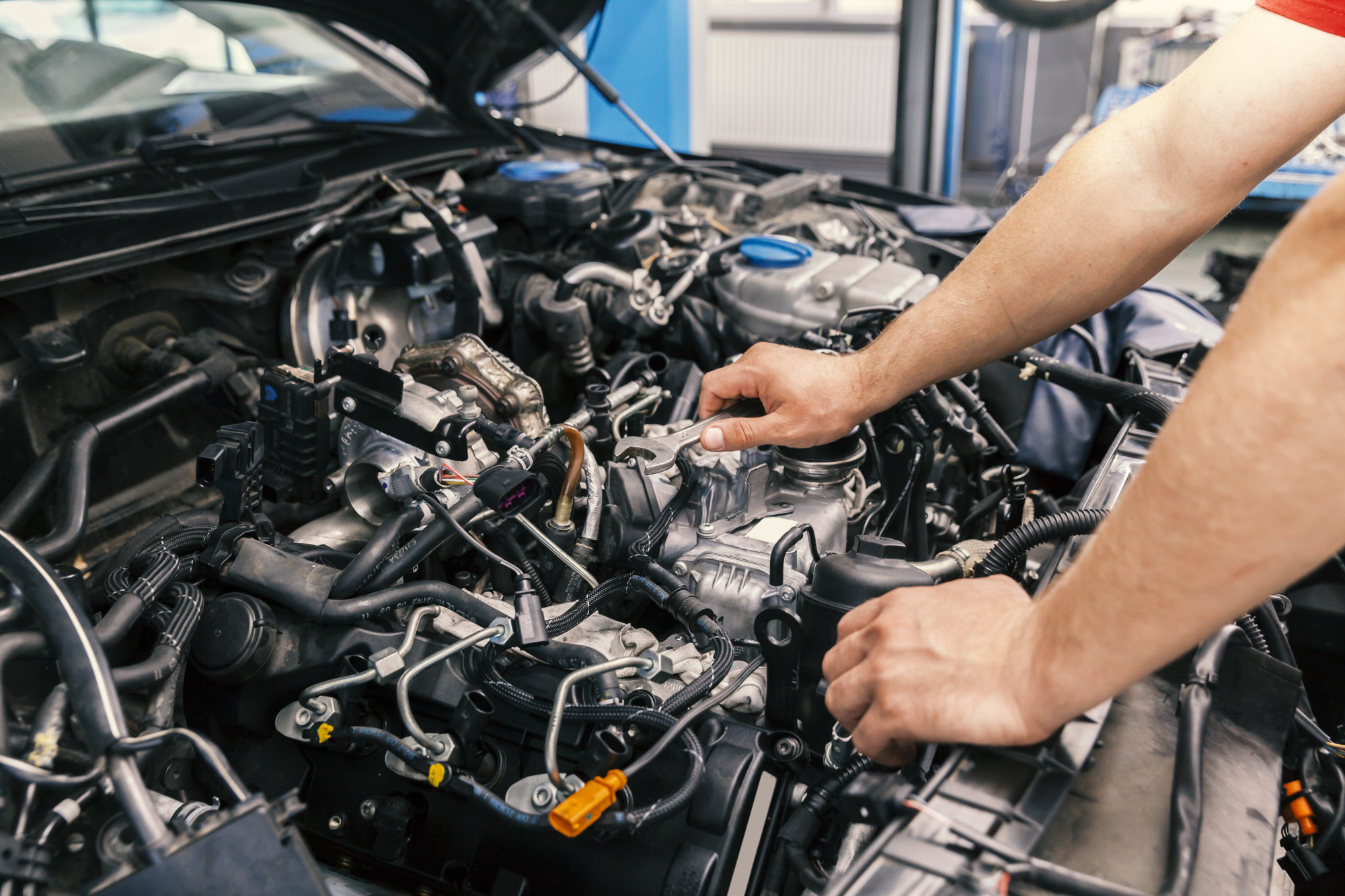

When drivers see the oil pressure warning light appear on the dashboard they need to take immediate action. Unfortunately, the possible causes for the light to come on run the gambit of extremely serious situations or minor problems. Here in this article we’ll talk about both of these major and minor root causes. With this information drivers will perform a few checks and determine a course of action.

Overview of Oil Pressure Problems

Automobiles come equipped with an oil pressure gauge and or a warning light. Unfortunately, most of these automobiles get a simple sending unit that turns on a red oil pressure warning light. These sending units are simple pressure operated switches. They mount in an oil gallery and the pressure of the oil pushes up on a contact arm that opens the switch to turn off the lamp. Therefore, most of the sending units remain in the closed position when no oil pressure exists.

Obviously, the light notifies drivers to turn off the engine or damage could occur. DIY minded people can make some basic checks to determine whether they’re getting a false reading from a defective sending unit or if their problem represents a serious issue. The obvious first step when drivers see the oil pressure light come on is to pull the dipstick and check the oil level. A Low oil level causes low pressure and therefore turns on the light.

You can refer to your auto repair manual or owner’s manual for the location of the dipstick, the type of fluid and capacity required for your specific automobile. After taking this all important first step it’s time to move on to the other possibilities if the light remains on. In this article we’ll talk about the simple things and the best case scenarios, then work our way down to the more serious internal engine problems.

Checking the Oil Pressure Sending Unit

Diagnosing problems with the oil pressure sending unit really become a model specific operation. Some cars have a simple two wire switch that turns the oil pressure warning light on and off. Some automobiles feed power to the electric fuel pump through the sending unit. This gives manufacturers a layer of protection if the engine is suffering from an oil pressure problem. If the switch turns on the light it turns off the fuel pump to stop the owner from running the engine to destruction.

In the case of a simple two wire oil pressure sending unit you can simply unplug it and see if the light goes off on the dash. If this is the case and the light comes back on when you plug it in, you know the sending unit is commanding the oil pressure warning light to illuminate. This however, doesn’t mean the sending unit itself tests good. It means you confirmed the proper operation of the wiring and the.

Here’s the proper way to diagnose an oil pressure sending unit. First you remove the sending unit from the oil gallery and install a trusted mechanical oil pressure gauge. Then you start the engine and take an oil pressure reading. On new automobiles you would like to see 30 psi of oil pressure at idle. On older cars with more than 100,000 miles 15 to 25 psi keeps the light off on most models. If you see these pressures then you have a bad sending unit. As an alternative method just go ahead and replace the sending unit. The average cost of a replacement sending unit falls in the $20-$50 range.

Most Common Oil Pressure Problem

As a certified mechanic with 30 years of experience I have seen my share of oil pressure warning lights. Unfortunately, the most common thing I find with this complaint remains a lack of car maintenance. This rings truer on automobiles with over 100,000 miles or older than 10 years. When car owners neglect to change the oil and filter as recommended by the manufacturer problems result.

Specifically, the oil starts to thicken and develop sludge. This sludge settles to the bottom of the oil pan and clogs the oil pump pickup screen. When this happens, it restricts the amount of oil flowing to the pump and therefore throughout the engine. Automobiles with this problem often have a flickering lamp or an oil pressure warning light that comes on and off around turns and stops.

The only way to truly diagnose a situation like this is to remove the engine oil pan and perform an inspection. With that said, when I find sludge in the bottom of the oil pan, I’ll also find sludge throughout the engine. If we caught this soon enough it’s possible to soften the sludge and flush it out with engine flush type products. This is why jumping on the oil pressure warning light problem as soon as possible becomes so important.

Oil Pressure Warning Light the Worst Cause

The worst possible situation that can cause the oil pressure light to Flicker or stay on becomes a worn out engine. These motors usually show more than 150k or 200,000 miles on the odometer. As mentioned throughout this article, the oil pump sends pressurized oil through a network of passageways in the engine block. The two primary locations this oil flows to first are the camshaft and crankshaft bearings.

Pumping oil into these critical areas provides resistance. It’s this resistance that develops the amount of pressure from the oil pump. In fact, we can go as far to say the tighter the clearance the higher the pressure. This is why brand-new engines enjoy higher pressures than motors with 100,000 miles or more. The more the bearings wear the larger the clearances become and you start to see the oil pressure fall off.

This worst-case scenario of a worn out engine causing oil pressure warning lights to come on remains verifiable. In fact, you use the same tool that I mentioned for checking the oil pressure sending unit. First, remove the sender and install a trusted mechanical oil pressure gauge. On a hot engine you should see more than 15 psi of oil pressure on a warm or hot engine. If no sludge exists and the oil pump screen shows clear, then you could be looking at excessive clearance in the bearing area. Removal of the engine oil pan and checking the clearance of the crankshaft bearings with a product called plastic gauge verifies these excessive clearances.