If you’re shopping for scan tool you may have seen some entry-level offerings that come with fix assist, codes connect or something like it.

This is an aftermarket manufacturer hosted database of common repair problems and their technician reported solutions. This article attempts to make sense of these kinds of services.

See how they can both hinder and benefit a do-it-yourself effort to get their car fixed right the first time. Here’s a little explanation into some of the terms I used in the first paragraph. Entry-level does not relate to the cost of the scan tool itself.

It more refers to an offering from a tool manufacturer that is targeted for do-it-yourself mechanics. Stated another way, a manufacturer specific scanner like a GM tech II commonly used on General Motors vehicles, will not offer a service like fix assist.

A mechanic at a dealership will have access to factory issued technical service bulletins to aid in their diagnosis if needed.

The vehicle manufacturer also anticipates that the technician holding the tool has a high level of expertise. These technicians are expected to easily solve complex automotive problems and display knowledge about the specific product being serviced.

He or she will not need assistance, but you might. Here is a little more information about the database these aftermarket scan tools pull their data from.

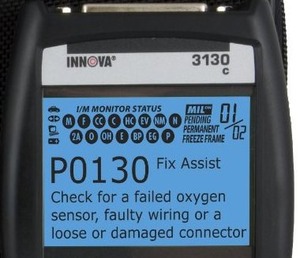

As an example Innova has a database they manage and connect too certain models of tools they offer like the 3130C. This service is called Fix Assist.

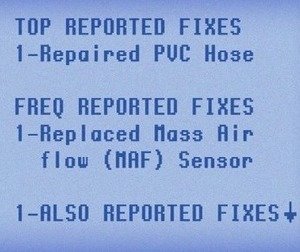

Actron, another popular brand with products in the same price range offer a service called Code Connect where they boast 4.3 million vehicle specific fixes categorized by the sub system the fault is in. These check engine light trouble codes are extracted from the power train control module.

Problems with Database Solutions

You can really boil down the problem with these types of one-size-fits-all solutions with a saying my first automotive instructor told his students over and over again. He said “when it comes to an automobile there are two words that cannot be used. These words are always and never“.

I can verify this to be true as over the last thirty years of fixing cars I’ve had more than a few incidents of uncommon failures and even stranger solutions.

This brings us to the main problem with having the code connect and fix assist databases tell us what’s wrong. They provide a short or sometimes longer list of things that can cause the issue being experienced.

In some cases this list of things is helpful in diagnosis, but ultimately the problem could lie in something that isn’t listed at all. When this occurs chasing after the problems that are listed can be a time waster, a wild goose chase, exercise in futility or all of the above.

I have found some driveway mechanics can become extremely angry when their individual failure turns out to be something like a broken vacuum line if they’ve spent money on replacing an oxygen sensor.

Sometimes Code Connect or Fix Assist Works

As a mechanic I would like to get one thing straight on how I feel about a collected database of possible solutions. In short, I like them.

Even though I just got done saying all kinds of bad things about it I like to know what fixed certain problems. It’s how you use this information that is more important then it being provided in the first place.

As an example, if you set a throttle position code the auto repair database will probably have solutions like defective TPS sensor, poor connection or wiring problem and ECM malfunction.

Some driveway warriors might take the first piece of information, which is defective TPS sensor and buy a replacement, instead of digging in and performing diagnosis.

First of all the scan tool you have is probably capable of pulling up the data stream for that sensor. This means with the key on engine off, you can push down gradually on the gas pedal and watch the throttle position voltage change in real time. This diagnostic test can also be performed with an automotive voltmeter at the sensor by back probing the reference signal wire with the part connected. If the sensor is defective it will often fall to 0 V somewhere along the range of operation.

This is known as a dead spot as a TPS should never read 0 V. Therefore the information from fix assist or code connect indicates the sensor should be tested not just replaced.

Now it’s time for you to make a decision about what automotive scanner is right for you and your budget.

Nevertheless, the fact it comes with a service that provides possible solutions to your problems shouldn’t really have any determining factor in your ultimate choice.

You can ignore the service and your scan tool works just fine. Or you can browse through the common failures for your given check engine light code and take those solutions with a grain of salt.

Remember that further diagnosis and confirming failed components is always necessary with or without fix assist or code connect. Review more detailed information about the dreaded check engine light.

Visit the homepage to find out what other kinds of do it yourself auto repair information is available here.